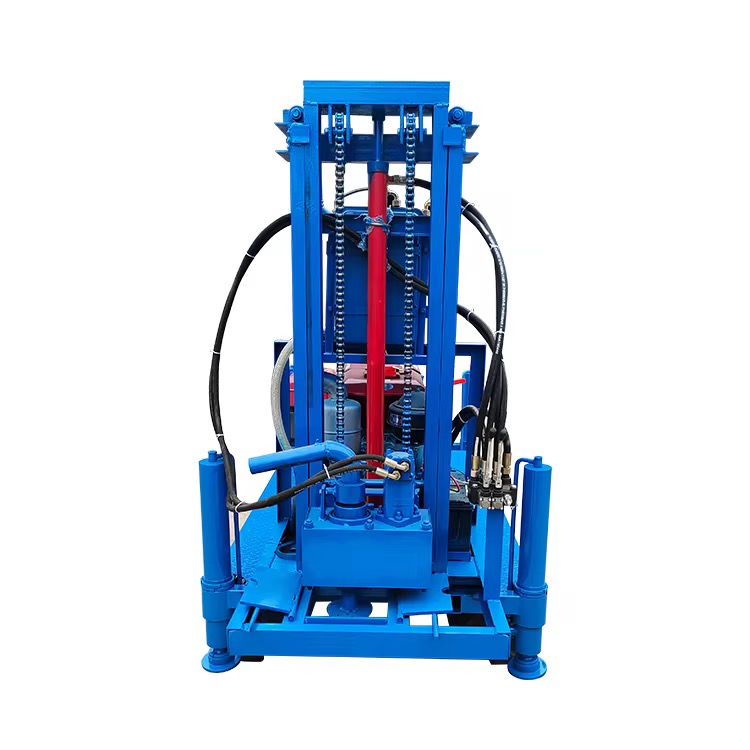

Well Drilling Rig: An Overview

A well drilling rig is a complex assembly of equipment designed to bore holes into the earth’s subsurface for various purposes, including water extraction, oil and gas exploration, geothermal energy, or environmental monitoring. Below is a structured breakdown of its key aspects:

1. Components of a Drilling Rig

-

Derrick/Mast: A tall structure supporting drilling equipment and hoisting the drill string.

-

Drill String: Series of connected pipes transmitting rotational force to the drill bit.

-

Drill Bit: Attached to the drill string, it crushes or cuts through subsurface formations.

-

Rotary System: Rotates the drill bit (e.g., rotary table or top drive).

-

Hoisting System: Winches and cables for lifting/lowering the drill string.

-

Mud Circulation System: Pumps drilling fluid (“mud”) to cool the bit, remove cuttings, and stabilize the wellbore.

-

Blowout Preventer (BOP): Critical safety device in oil/gas drilling to control pressure surges.

2. Types of Rigs

-

By Purpose:

-

Water Wells: Smaller, truck-mounted rigs for shallow depths.

-

Oil/Gas Rigs: Larger, more powerful, often with advanced pressure control systems.

-

Geothermal Rigs: Designed for high-temperature environments.

-

Environmental/Monitoring Wells: Portable rigs for sampling or remediation.

-

-

By Location:

-

Onshore: Includes portable truck rigs or heavy land-based rigs.

-

Offshore: Platforms, drillships, or jack-up rigs used in oceans.

-

3. Drilling Methods

-

Rotary Drilling: Most common; uses a rotating bit with circulating fluid.

-

Percussion/Cable Tool: Traditional method using a repeatedly dropped heavy bit.

-

Auger Drilling: Screw-like drill for soft soils.

-

Directional Drilling: Allows angled or horizontal wells for resource access or minimal surface disruption.

4. Applications

-

Resource Extraction: Water, oil, natural gas.

-

Geothermal Systems: Installing ground-source heat pumps.

-

Environmental: Monitoring groundwater or installing remediation wells.

-

Geotechnical Investigations: Soil sampling for construction projects.

5. Drilling Process

-

Site Preparation: Clearing land, securing permits.

-

Drilling: Rotating/driving the bit while circulating fluid.

-

Casing Installation: Steel/plastic lining to prevent collapse and contamination.

-

Cementing: Sealing the casing to isolate formations.

-

Completion: Installing pumps (water wells) or production equipment (oil/gas).

-

Decommissioning: Plugging abandoned wells to protect groundwater.

6. Environmental & Safety Considerations

-

Contamination Prevention: Proper casing and mud disposal to protect aquifers.

-

Regulations: Compliance with local laws on well construction and fluid management.

-

Safety Protocols: Pressure control (BOPs), crew training, and emergency plans.

7. Challenges

-

Geological Uncertainty: Unanticipated rock formations or fluids.

-

Depth/Terrain: Deeper wells require robust equipment; remote sites need portable rigs.

-

Cost Factors: Depth, terrain, and regulatory hurdles influence expenses.